Spoke offset bed

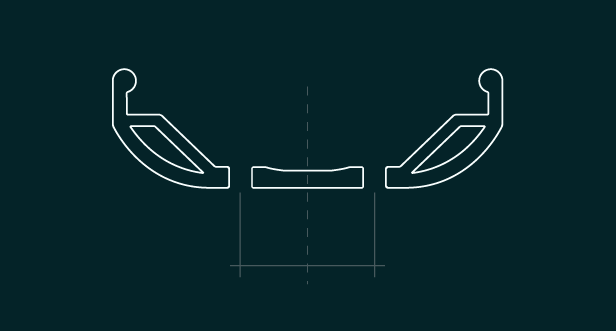

Asymmetric rim design and offset spoke bed measurement were covered in the article Measurements for wheel building - Taking your own measurements with confidence. Contrary to the standard, symmetric rim design, where a rim has holes positioned straight in the middle, spoke holes of asymmetric rims are offset from the center of the rim.

The purpose of the spoke offset is to help minimise the right and left spoke tension difference. This is achieved by pointing the spoke hole offset of a rim towards the side of the wheel where spokes would otherwise have a higher bracing angle. In that way, both sides should have closer to the same spoke angle and tension across sides should be more balanced. Return to the article - Wrong spoke length - to get the idea to what extent a spoke offset bed measurement affects the correct spoke length. On my actual rear wheel example, changing the OSB from 0 to 1 mm shortened non-drive side spokes by 0.12 mm and lengthened drive side spokes by 0.06 mm.

Note: When using asymmetric rims and offset spoke bed measurement, make sure you filling out inputs of a spoke calculator for the correct side of the wheel. Put it simple, if you are calculating the front wheel, make sure you are filling the inputs under the Front Wheel Calculator. Calculator will then adjust WL and WR accordingly.

In one of their latest wheel building video on YouTube, Park Tool shows how to deal in practice with asymmetric rims and how to take measurements of spoke offset bed (OSB). Watch the video starting from 07:11 to see how a rim offset measurement is taken and used later on (from 15:00) in an online spoke calculator, featuring spokecalc.io.

VIDEO CONTENTS

00:00 Video start

00:25 Preliminary info

01:21 Typical Tools

01:51 The Spoke

03:49 The Rim

07:11 Rim Offset

09:01 Hub Dimensions

12:01 Lacing Pattern

13:01 Differential vs. Non-Differential Spoke Lengths

15:02 Online Spoke Calculators

Paired rim holes

Another peculiarity regarding rim measurements are grouped spokes on the rim side of a wheel. Spokes, paired in groups, may not appear only on the hub side which I covered in one of my previous articles, Exotic Wheelbuilding: Understanding paired spoke hole hub design.

Lately we are experiencing more and more exotic lacing patterns that include grouped spokes on the rim side also. In such cases, drive or non-drive side spokes are not equally spaced apart round the rim’s inner hoop regardless of the fact that rim holes may be equally spaced around the rim. Instead they are paired together in groups. This is also a situation where an ordinary online spoke calculator’s algorithm fails to deliver the correct spoke length.

2:1 spoke lacing pattern is one of the most obvious exotic spoke lacing patterns on the rim side. Just recently, an article on 2:1 lacing pattern, based on Fulcrum Wind 55 DB wheelset, showed how to modify spoke lacing pattern to get the correct spoke length.

The phenomenon of grouped spokes on the rim side rises to an even greater extent if you take a look at Campagnolo’s unique G3 geometry, where spoke lacing pattern comprises groups of three parallel straight-pull spokes, arranged in a 2:1 ratio with a substantial gap in the rim between these groups. Campagolo says in such lacing pattern, energy transfer and lateral rigidity are improved, and spoke tension is optimised, reducing stress and increasing lifespan.

Calculating the correct spoke length in such unconventional cases requires modifying spoke lacing pattern by adding a partial or a cross correction lacing pattern which leads to a final fracture number spoke lacing pattern. Read the article 2:1 Two-to-one lacing pattern - Calculating spoke length for a 2:1 spoke lacing pattern, to understand how the underlying logic of this unconventional lacing pattern is derived.

Alternating spoke offset bed

Most rims are centrally drilled, or with a negligible left/right spoke hole stagger. The other case is a uniform spoke offset bed (OSB), where spokes are off to only one side of a rim, typical for asymmetric rims, that we covered in the first part of this article. But there is yet another spoke hole layout in the rim that can affect spoke length calculations.

Some wide rims tend to have spoke holes slightly offset to alternating sides. Contrary to the conventional rims where looking at the cross-section of the rim the width between the holes is zero, spokes from the one side of the hub can cross past centerline and over to the opposite side of the rim. In such manner, spokes are alternating from one side of the rim to the another.

In wheel building terms, this situation is also called a “wash”. This leads to increased bracing angles and greater overall spoke tension in effect throughout the wheel to maintain the structural equilibrium of the wheel.

Leaving lacing and tensioning matters aside, how does alternating spoke offset bed affect our rim measurements and spoke length calculation?

Such a rim should not be considered as an asymmetric rim, and so the offset spoke bed (OSB) should be left at zero. Of course, one could argue using an alternating positive and negative offset spoke bed measurement, but for the purpose of this article, there is yet another, easier possibility.

Instead, if there is a measurable gap between the left and right spoke holes, effective Flange to center dimensions, WL and WR respectively, should be modified accordingly (increased or decreased) to compensate for offset spoke holes in the rim.

If there is a 10 mm gap (width) between spoke holes, looking from the rim’s centerline, alternating spoke offset bed should be 5 mm respectively. If the rim spoke hole stagger indicates that spoke from one hub flange side should cross over to the other side of the rim, both Flange to center (WL/WR) dimensions should be increased for 5 mm and vice versa if a rim spoke hole angle suggests otherwise.

Note: Always double check the spoke hole stagger in the rim as the angle of drilling defines to which side of the hub should the spoke be going.

Final thoughts

In addition to effective rim diameter, different rim designs and spoke hole layouts affect spoke length calculation noticeably and as such should be considered with great care when taking measurements. Looking at asymmetrical rims, it is a fairly straight forward process of entering the correct offset spoke bed measurement. On the other hand, most online spoke length calculators just aren’t designed for the other two rim holes layouts. Therefore, as shown, some modifications of calculator input’s values have to be made in the process of determining the correct spoke length.

Happy wheel building!